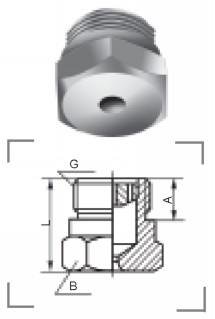

QZ1

The nozzle is marked with novel structure and even atomization. With the stationary cyclone core, the performance is stable. It is mainly suitable for the secondary cooling in continuous casters for square/round billet, and can be also used for equipment where the temperature needs lowering in sintering, chemical industry and others.

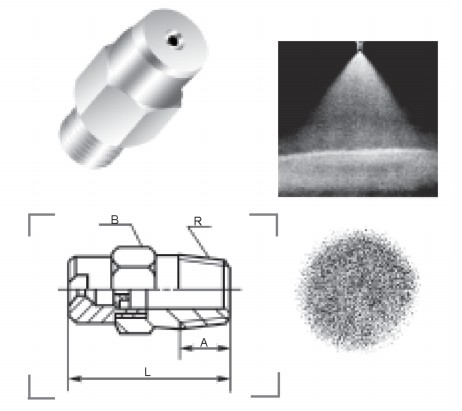

QZ2

The nozzle is in the type of stationary cyclone core. Its spray pattern is in the shape of a full cone; and the spray is distributed evenly. It can be used for the secondary cooling in continuous casting and all machinery equipment that needs cleaning.

QZ3

The nozzle has a movable cyclone core and is in compact structure. The spray pattern is in the shape of a solid cone, with even distribution and stable performance. it is mainly used for the secondary cooling in special steel continuous casting and can be also used for the cooling of electric dedusting and spray painting and other procedures.

QZ4

The nozzle has a stationary cyclone core. The spray pattern is in the shape of a solid cone. It is suitable for the secondary cooling in the bloom-billet and slab continuous casters for special steel, and can be also used for cooling and cleaning in spray painting, electric dedusting and other processes.

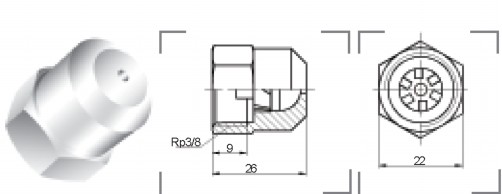

QZ5

The nozzle has a compact structure. The spray pattern is in the shape of a cone, and the nozzle can be easily installed. It is mainly used for the secondary cooling in bloom/billet continuous caster, and can be used for decontamination, air-purification, etc.

QZ6

The nozzle is marked with a compact structure, even atomization and easy installation. Its spray pattern is the shape of a cone . It is mainly suitable for the secondary cooling in billet continuous casting, and can be also used in environmental protection, air-purification and cooling of machinery.

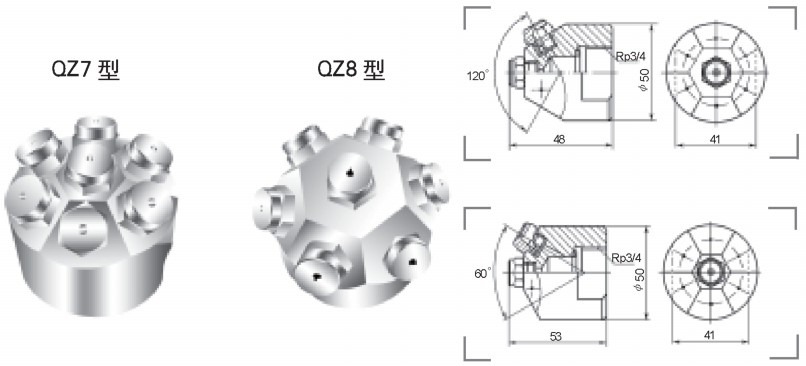

QZ7/QZ8

The nozzle make many types of jet flow of solid cones. The jet flow makes up a solid full-coverage spray pattern and the power can be increased when the droplets are getting smaller. There are seven nozzles on the nozzle body, therefore the installation and application are very convenient. The nozzle is mainly used for cleaning, environmental protection and the secondary cooling in special steel slab continuous casting .

QZ9

The nozzle is marked with a compact structure, easy installation, even spray distribution and etc. Its spray pattern is in the shape of a stationary cyclone core. It is mainly used for the secondary cooling in continuous casting billet, and can also be used for the cooling of other processes.

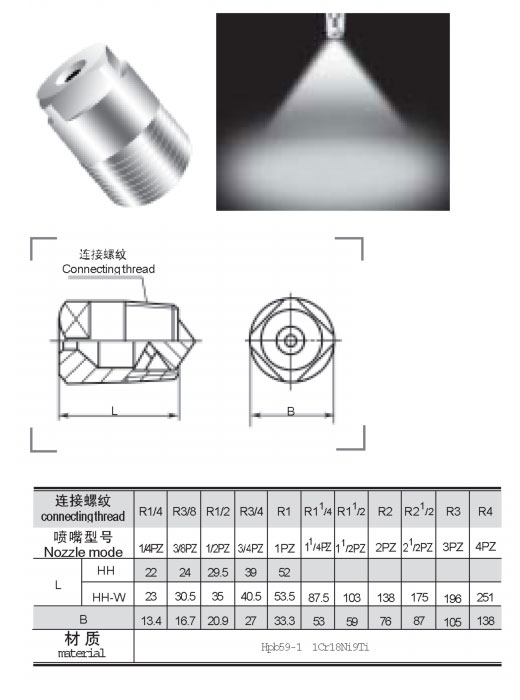

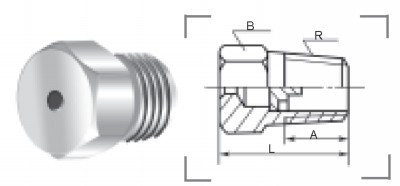

QZ10

The nozzle has a new structure. Its spray pattern is the shape of a solid cone, with even atomization. It is mainly suitable for the secondary cooling in continuous caster for bloom/billet and slab. It can be also used for the electric dedusting, spraying painting and all mechanical equipment that needs cooling.

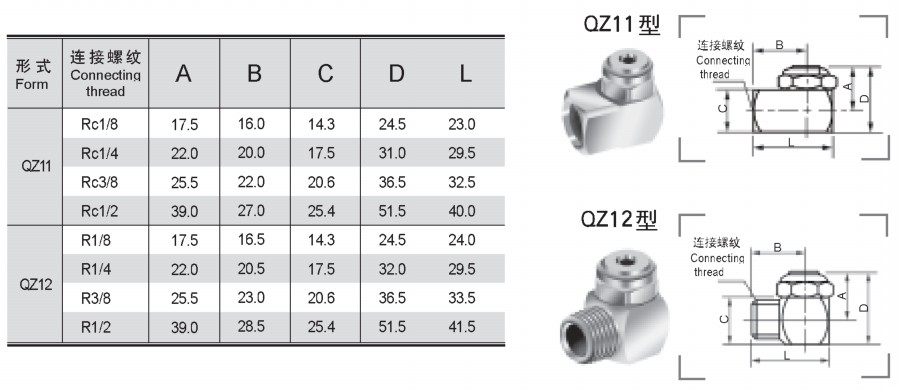

QZ11/QZ12

The spraying pattern of the nozzle is the shape of a solid cone. The axis of liquid sprayed makes an angle of 90 to the axis of nozzle inlet. The spray area is an even cone shape and the nut can be easily removed. It is mainly used for dedusting and humidification of steam and air pipe and for the secondary cooling of continuous casting square and round bloom/billet.

Z13

This series of nozzle is marked with compact structure, even spray atomization and good technical property. It is mainly used for forced cooling of cast blanks in continuous casting and slab rolling. It is also suitable for rinsing and cleaning, spraing the surface of air and solid substance, and rinsing the filtering mat in the gas relay scrubber to improve chemical reaction.